The state of fashion digital transformation has taken a 360 degree turn in 2020 and the talks have now switched to ‘The industry MUST change’ from ‘The industry needs to change’. The conventional methods were not sufficient and effective enough previously to accelerate and rightly serve the fashion businesses, fashion professionals, consumers as well as the planet. The more digital disruption will mean more positive transformation of the way apparel industry designs, fits, manufactures, delivers, sells, and communicates with the stakeholders in the entire supply chain.

A recent conference of Alvanon, a leading fashion tech company, addressed these issues head-on and identified four key areas where a change must be effected. These areas are – Data Collection & Standards; Creating & Marketing; Production & Supply Chain; and 3D Skills Development & Careers.

Over supply has been a prolonged issue and digital ‘Data Collection & Standards’ can help reduce it…

Over supply has always been a problem for fashion and apparel industry and has been making dent on the profitability of the retailers as well as the manufacturers. The bigger problem here is that the retailers and manufacturers of apparels fail to utilise the available data for decision making at large scale and go only after their experiences or intuitions. This is the basis of more production, less relevance and unsold inventories in the retail shelves.

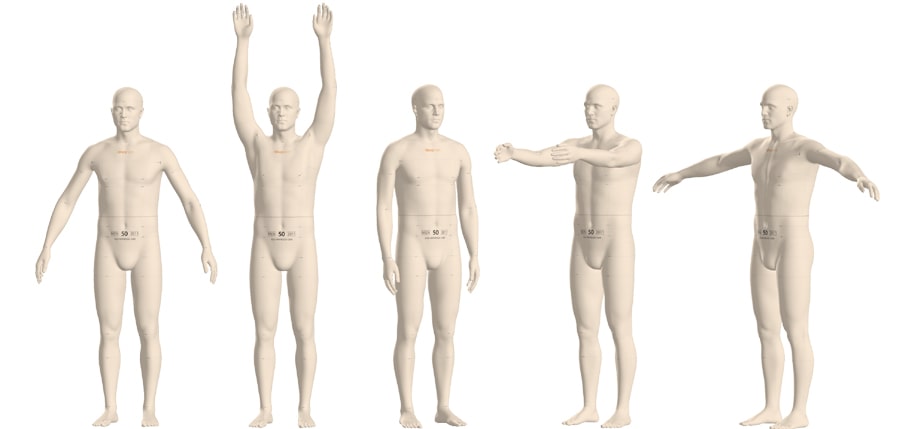

According to Alvanon, standardisation is key and data-driven standards must underpin all product development, pushing companies to use data to generate standards on the size, shape and demographic characteristics of its target consumers. Digitalisation and data-driven approach enable companies to standardise and share all their critical standards information and tools in a hub that, everyone who needs to, can access. A library of agreed, defined and consistent standards that would include body blocks, fabrics, fit standards and 3D avatars – must form the basis of all product development. These ‘Asset Libraries’ are the key to generating ‘Authentic Digital Garments’, that is digital garments that are truly representative of the physical product.

Terming this whole need as the basis of ‘the authentic digital garment’, Jason Wang, COO, Alvanon stated that digitalising workflow can only happen if a company has built an ‘authentic digital garment’ library of high-quality digital assets. The first step is to understand, create and define the size and shape standard for a target consumer population.

Also Read: Alvanon navigating industry to reduce lead time and iteration through digitalisation

Though ‘authenticity’ is a key requirement of an authentic digital garment, the fashion professionals across the product life cycle must trust that the digital garment is the same as the physical product and these authentic digital garments can then be confidently and quickly generated and modified in the virtual world before committing to more costly and wasteful physical samples.

Having an authentic digital garment library of all core products, can cut physical sample production by up to 80 per cent. This library of authentic digital garments will become one of the most important shared assets for any apparel company, if implemented correctly. “We have an opportunity today with the technology and tools available to us, to build a new future for the apparel industry. One where the digital and physical are closely connected and work together,” told Jason.

‘Creating & Marketing’ is key for digital boost of the industry…

It’s an undeniable fact that digital imagery has been helping the way fashion and apparel product is being designed, sampled, produced and sold but the efforts in this area need to intense. The industry has also seen a rise in the use of realistic human-like avatars in catwalk and social media campaigns where celebrity virtual models and powerful social media influencers are all reshaping the online experience and consumers are sort of loving these virtual representations of a human world.

The rendering techniques that create the lifelike images and animations are still in their infancy but in the hands of those who know how to use these tools; the results are compelling and powerful. Indeed a portfolio of digital models wearing properly rendered designer garments in catwalk settings or virtual super influencers that can drive trends, will appeal to brands and consumers alike.

Endorsing the need of creating a successful digital runway in 3D, Cameron-James Wilson, CEO and Creative Director, The Diigitals – the first all-digital modelling agency in the world which has been behind some of the most innovative 3D fashion campaigns lately – asserted, “Everything involved in creating the digital catwalk is ‘super achievable’. Companies must have the vision and understand the workflows needed.”

For example, the companies need to understand the workflow in garment digitisation which is – design concept and patternmaking; pattern and fabric; still images (post and simulate). Each outfit is created from original sketches, photos and pattern pieces. The garment and model are then textured, posed, placed into the final scene and then rendered. Still renders take a few hours to process, while animations take days. One animation on the Digiitals runway took 36 hours to render for five seconds of catwalking.

The Diigitals has also created some ‘shop the look’ stories for Instagram, which helps with engagement and shows clients how these assets can be used. These are ideal for social media campaigns and consumers really engage with 3D renders of clothing and models. Even after physical shows return, the industry professionals will expect the use of digital 3D tools will permanently shift the schedule, cadence and strategy of virtual catwalk shows. “I am all about making things accessible, sharing workflows, and just being open and honest because I want to see this industry achieving its best. I want to see what people can really create with similar sorts of assets.”

The impacts on ‘Makers & Supply Chain’…

The adoption of an end-to-end digitalised product design, development and management strategy is said to yield significant benefits for everyone involved in the supply chain. According to Alvanon, the design and product pre-development time can be reduced by up to 50 per cent, while workload and sampling time can be brought down by 30-60 per cent and the first time right performance can be increased by up to 50 per cent. Such significant improvements in efficiencies means apparel companies can be more responsive, flexible, transparent, sustainable and consumer relevant.

However, to succeed, it requires both technological and cultural transformations to the core level. In addition to technology investments, brands and retailers must simplify their supply chain and forge meaningful partnerships with their suppliers, where mutual and supportive technology investments are implemented, shared and understood.

A case study of VF Corporation…

When it comes to digitising the Go-To-Market process, VF Corporation stands apart with its digital innovations and fruitful results. Joshua Young, Director of Digital Product Creation, VF Corporation is a world authority on digital transformation for the fashion industry and has helped brands such as VF, Nike, Patagonia, PVH, Carter’s and Lululemon in their endeavors of reducing costs, shortening the lead time and increasing the sales via better decision-making enabled by digitalizing their assets and workflow.

He has laid a process in order for the industry to leverage digital transformation that starts with ‘new processes, new methods, new materials, new tools, new roles and new ways to sell.’ According to Joshua, it is not just about investing in new 3D software, instead this requires changing the way fashion companies work internally and with vendors and suppliers.

New Processes:

3D Concepting; Digital Design, Digital Prototyping and Sampling; Visual Merchandising; Digital Retail Planning; Digital Selling; 3D consumer experience

New Methods (Factory Partners/Digital Samples):

Reduce physical prototypes and samples; reduce costs and simplify logistics; increase product development speed, better quality product – fit & accuracy; more sustainable; increase desirability

New Materials (Supplier Partners/Digital Materials):

3D Samples need 3D Materials, Material teams working from home; Elimination of material fairs; Teams buying materials online; Designers creating digitally

The Benefits: Welcome to the Digital Swatch Card; Sell to brands & increase sales; Reduce costs and simplify logistics; Speed developments (Digital Strike-Offs); Open new (digital) markets; More sustainable

New Tools (Digital Tools Equal/New Capabilities):

3D is the new paintbrush; Visualise shape, flow and volume; Fully express design intent; New ways to reach the consumer; Skill is skill, craft is craft in physical, 2D, 3D

New Roles (Invest in People/Digital Skills):

Empowering people accelerates change; Retrain, reskill, redeploy; Digital processes in education; Brand/Education partnerships

New Ways to Sell:

How do we get up close and personal with the product? Vans Custom Shoes – this is the industry’s best 3D customiser, as claimed by VF Corp.

Skill development is key to realise potential…

Many of the skills required to realise the potential of 3D digital technology investments are new and emerging; such is the advanced pace at which the technology is moving. Therefore, upskilling workforces, partnering with academic institutions and an investment in continual learning programmes are imperatives to continued success.

Employing digital natives to plug the skills gaps is not enough. Even their skills will be displaced by new tools and they do not have the experience of making things. Existing practitioners know what works in the physical world and hence the companies’ transitioning into a digital way of working must also support their existing workforces and foster a ‘learning mentality’ across their people and teams, as believed by Alvanon and MOTIF, an apparel knowledge hub that connects professionals around the world with skills they need to transform.

MOTIF conducted a global skills survey in 2020 to take the pulse of the fashion industry and assess the level of investment in skills by apparel professionals and companies. Over 900 apparel professionals from across the value chain took part in ‘The State of Skills in the Apparel Industry 2020’ report, supported by 19 apparel industry associations. The survey also endorsed the fact that, while there is clearly still a need for strong fundamental skills (like apparel costing, sourcing, supply chain management, etc.) one key finding was the perceived gap in ‘future skills’ that combines 3D digitalisation and data skills with technical skills.